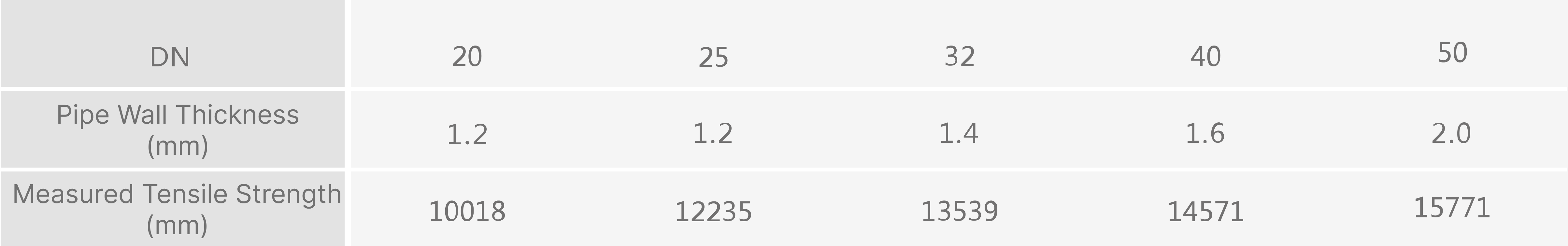

Rated Working Pressure: Gas / Liquid=1.6MPa(Standard Type),2.5MPa(Thickened Type) Gas (Fuel)≤0.4MPa

Application Range: Cold/hot water, drinking water, fire protection, compressed air, nitrogen & inert gases, medical gas systems

Working Temperature: Gas -40℃~120℃ Water 0℃~100℃

Standards (China National Standards):

GBT-33926-2017 <Annular Crimp Stainless Steel Fittings>

Q/74364329-3.2 <Low-pressure Fluid Annular Crimp Stainless Steel Fittings>

CECS305-2011 <Technical Code for Annular Crimp Piping Engineering>

GB/T29038-2012 <Technical Specification for Thin-wall Stainless Steel Piping>

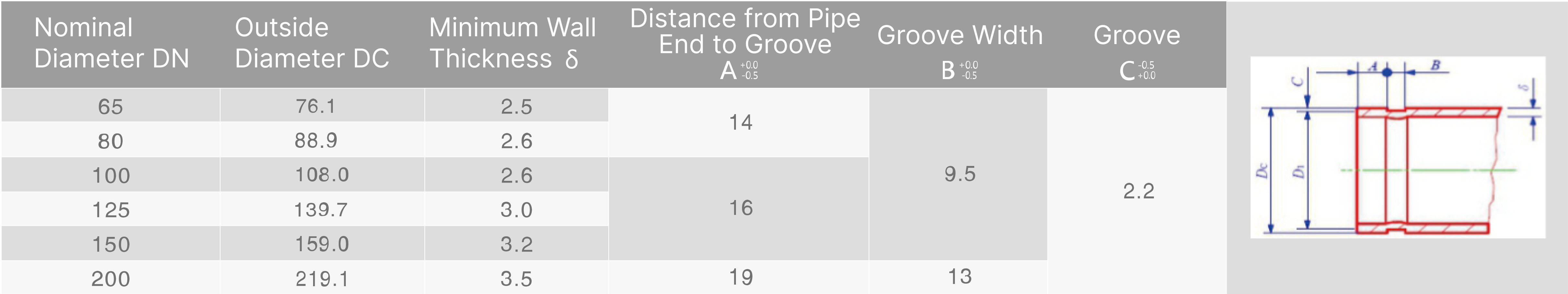

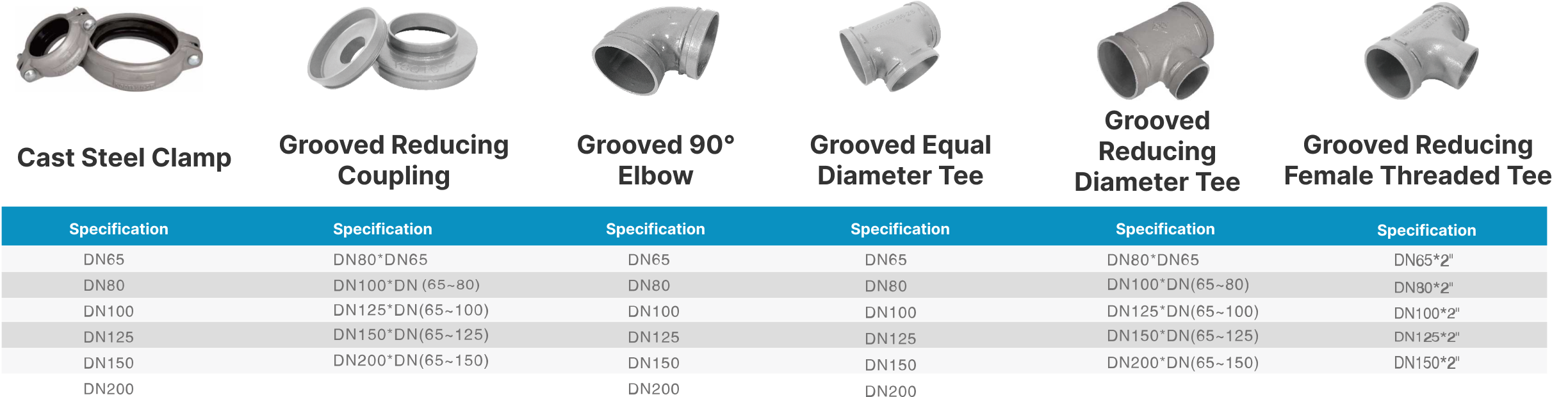

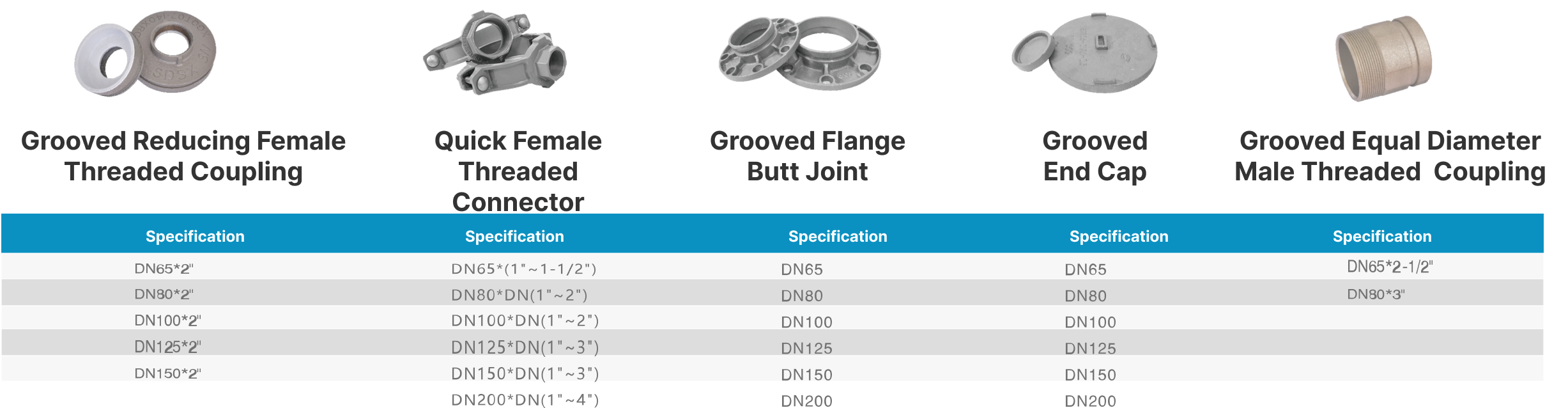

Rated Working Pressure: 1.6MPa,2.5MPa

Application Range: Compressed air, nitrogen, and inert gases

Working Temperature: -40℃~120℃

Standards (China National Standards):

GB 5135.11-2006 <Grooved Pipe Fittings>

GB/T8259-2008 <Technical Requirements for Flexible Clamp-type Couplings>

GB/T 8260 <Dimensions of Flexible Clamp-type Couplings>