Due to the necessity and high energy consumption of air compressors in the industrial field, in order to balance industrial production and environmental protection, the country has successively introduced various energy-saving and emission reduction policies and regulations in recent years, aiming to reduce the energy consumption of air compressors and save energy.

Therefore, various energy-saving air compressors have emerged on the market, but is compressed air energy-saving just as simple as an energy-saving air compressor?

![]() Single machine energy-saving

Single machine energy-saving

Energy saving standards and quality assurance

The air compressor is the source of industrial gas production, and accurately matching the gas volume and pressure according to actual working conditions is the first step in energy saving for air compressors. In addition, choosing air compressor products with higher energy efficiency standards and safety and quality assurance is the key to further energy conservation.

Energy saving of gas stations

Reduce consumption with a face to face point system and customize precise matching according to needs

However, whether from the perspective of market demand or energy-saving space, traditional single machine energy-saving has become a thing of the past. Judging energy-saving standards through energy conversion ideas and considering the composition of the entire station building system is obviously more scientific and practical.

The first level energy-efficient air compressor station in Deman achieves a significant reduction in energy consumption through the use of advanced system energy-saving technologies and coordinated design.

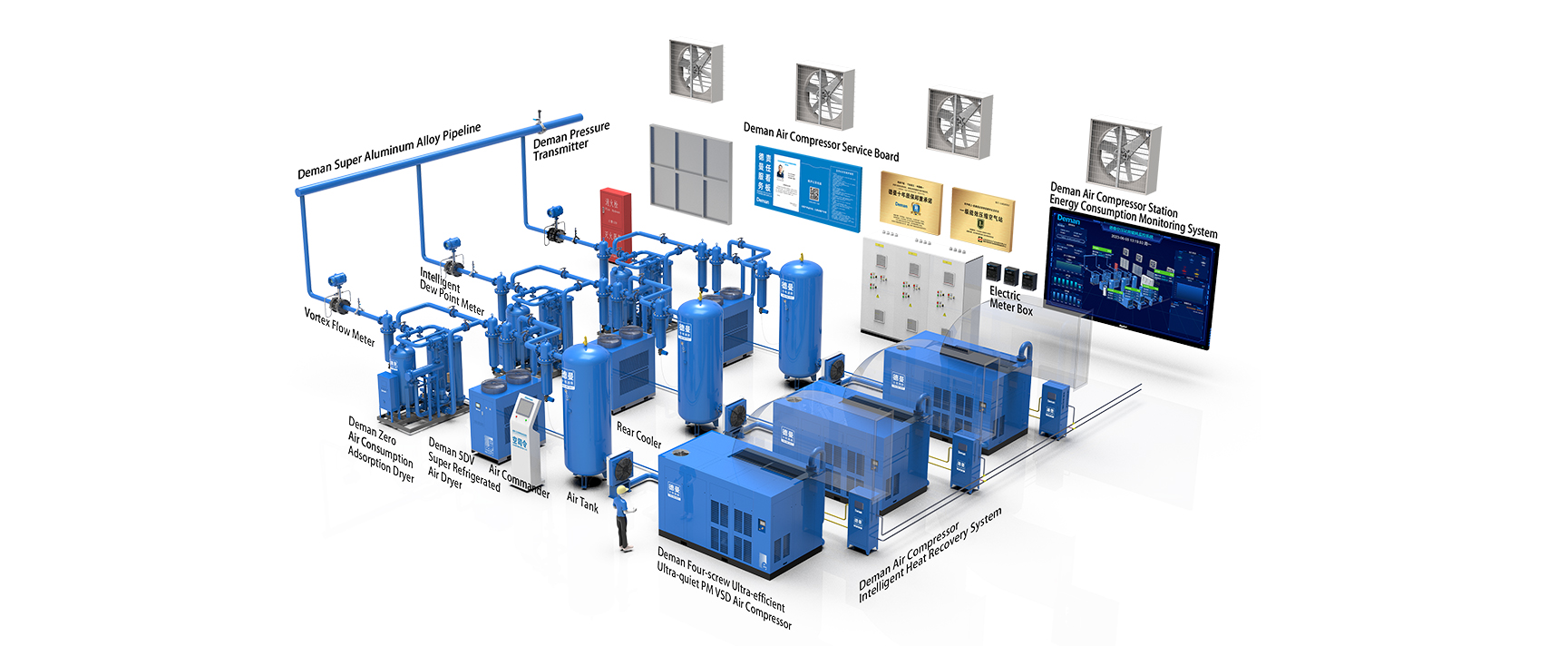

A new type of safe and energy-saving gas supply station is formed by combining customized energy-saving air compressors, pre buffering gas storage tanks, 5DV intelligent permanent magnet variable frequency super refrigerated dryers, high-efficiency filters, post buffering gas storage tanks, zero gas consumption drainage systems, intelligent control systems, exhaust channels, aluminum alloy green super pipelines and other gas production and processing equipment according to customer needs.

Deman’s Six-end Application

01 Planning

Make sure to understand the air pressure, air flow, and air quality requirement of each air use terminal at client's factory.

02 Air Production

By selecting the best combination of air compressors + air dryers+ heat recovery unit + "Air Commander" multi-compressor central control system, to match precise air pressure, precise air flow, and precise air quality with the air use terminal requirement.

03 Air Transmission

Use scientific design and installation of super aluminum alloy pipelines combined with stainless steel connection to achieve a green air network for the entire factory.

04 Application

Select high-quality pneumatic components, pressure control valves, flow control valves, and pneumatic tools, to help our customers optimize the application of compressed air, to improve air use efficiency and reduce energy consumption.

05 Cloud Management

Ensure production safety by using cloud-based early warning systems, so that abnormalities can be detected early, and use preventative maintenance to avoid potential failure and product halts.

06 Maintenance

We suggest to have comprehensive maintenance" every 3,000h. Regular maintenance of our air compressors and post-treatment system can ensure the long-lasting efficiency and reliability of installed units.