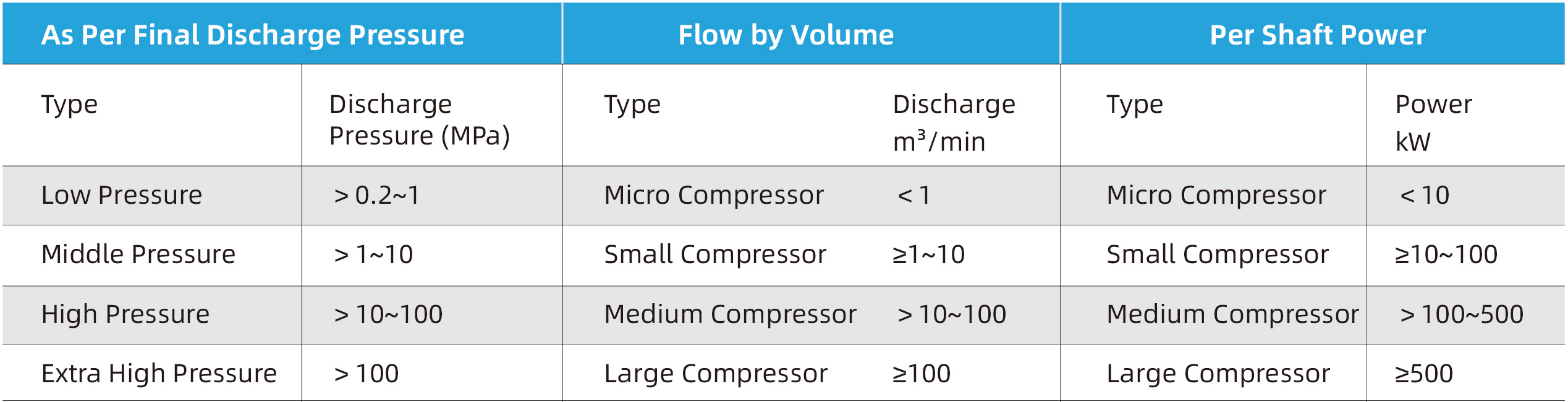

Air compressor is a widely used power equipment in various industries, whose main function is to compress and store air for supply to other equipment or processes. In its segmented field, we can usually classify it according to the final exhaust pressure, volumetric flow rate, and shaft power of the air compressor.

Among them, according to the final exhaust pressure, air compressors can be divided into low-pressure air compressors, medium pressure air compressors, high-pressure air compressors, and some ultra-high pressure air compressors used in special fields. Next, let's take a brief look at these three common types!

Low pressure air compressor

The output pressure of a low-pressure air compressor is usually between 0.2-1.0MPa. This type of air compressor is mainly suitable for some relatively simple processing techniques, with a relatively cheap price and simple maintenance.

It is widely used in production processes of textile, foam and other industries:

Textile industry: Compressed air is widely used in fiber material conveying, rubber roller pressurization, mobile workstations, jet air processing, jet self-control technology, cleaning components and other processes.

Foam industry: from foam raw materials into the machine for production, pre foaming, curing and molding, cleaning and cooling, the whole process of foam production requires the use of air compressor system.

Medium pressure air compressor

The output pressure of medium pressure air compressors is usually between 1-10 MPa. Compared to low-pressure air compressors, their exhaust pressure is higher, which can meet more processing needs, but the price and maintenance costs are also relatively high.

It is widely used in production processes such as die-casting and injection molding

Die casting industry: Compressed air is mainly responsible for controlling the flow rate of liquid metal, compacting parts, and ensuring that the pressure inside the mold is always maintained within a certain range.

Injection molding industry: Compressed air is used for cleaning spray equipment, casting blanks, inflating air objects during molding, inflating into tube shapes during extrusion, vacuum or pressure molding, cylinder operation, and other processes.

High pressure air compressor

The output pressure of high-pressure air compressors is generally between 10-100MPa, mainly used in processes that require very high gas pressure. Their price and maintenance costs are also very high, and strict adherence to safety operating procedures is required during use.

There are many applications in the production process of industries such as laser cutting:

Compressed air, as an auxiliary gas for laser cutting, plays a role in assisting combustion and heat dissipation during the laser cutting process, timely blowing away the molten stains generated by cutting, preventing the cutting molten stains from rebounding into the nozzle, and protecting the focusing lens.

As an important basis for selecting air compressors, insufficient pressure in air compressors will result in low production quality and efficiency of products, but for every 0.1MPa increase in pressure, it will increase energy consumption by 7-15%.

Therefore, it is crucial to choose a pressure machine model that is suitable for the production process configuration requirements. This not only greatly reduces the purchase cost of air compressors, but also has significant implications for enterprises to save energy consumption, ensure product quality, and reduce operating costs.