Project Background

Ningbo Changhua Changsheng Auto Parts Co., Ltd., a subsidiary of Changhua Holding Group, has a very high reputation in the automotive parts industry.

Originally, they used steam heating to clean raw materials, with steam costs amounting to over six hundred thousand RMB per year.

After several on-site inspections and discussions, Deman and Changhua Changsheng reached an agreement on a solution to use air compressor waste heat recovery to provide hot water.

Waste heat recovery refers to the process of extracting energy from the waste heat generated during industrial production or energy use for other purposes, thereby improving energy utilization efficiency and reducing energy consumption.

Waste heat recovery has a wide range of applications in various fields such as industry, construction, and transportation, and is an important means to achieve efficient energy utilization and environmental protection.

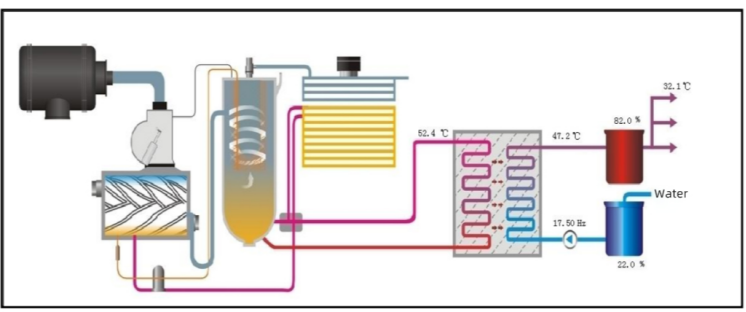

Deman's air compressor intelligent waste heat recovery system uses oil-water heat exchange to transform heat energy that would have been wasted into hot water.

• When the air compressor operates normally and the cooling oil temperature rises above the rated temperature of 75 degrees set by the temperature control valve, it enters the waste heat recovery heat ex-changer, transferring heat to the cooling water. It then becomes low-temperature oil and enters the air compressor heat ex-changer, before finally returning to the air end.

• Hot water transfers heat to the cleaning tank through a secondary heat exchange process. With the aid of an intelligent temperature control box, it ensures that the temperature of the cleaning tank meets the customer's requirements.

Therefore, the waste heat recovery retrofit of the air compressor provides a large amount of free hot water for the customer's cleaning line, replacing the original steam heating while maximizing the reduction of cooling system power consumption, further enhancing the energy-saving efficiency of the air compressor!

In addition, Deman waste heat recovery equipment uses the "Deman Cloud" remote control system to ensure real-time monitoring of water usage information. In case of deviation from the set data, timely early warning will be issued, and the Deman application team will promptly analyze the issues and provide remote guidance or on-site service to resolve issues!

Customer Energy Savings Benefits

In the Changhua Changsheng - Deman Thermal Energy Recovery Retrofit Project, Deman installed waste heat recovery devices and secondary heat exchange water heating systems on three 200kW air compressors for Changhua Changsheng.

Upon completion of the project, it has provided Changhua Changsheng with a continuous supply of stable and cost-effective hot water, as well as annual energy savings of 627,000 RMB! This has created infinite value for Changhua Changsheng's efficient air usage!