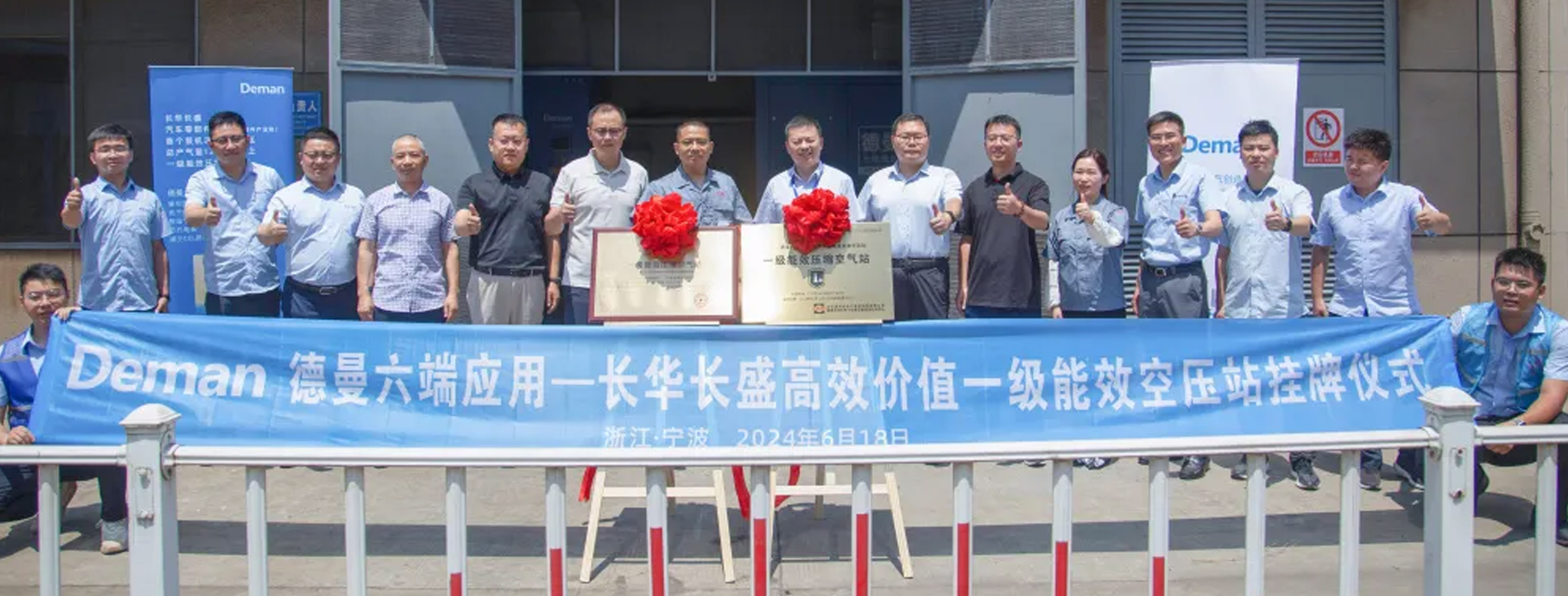

Recently, the grand ceremony for Deman's “Six-End” application - Changhua Changsheng high efficiency value Grade 1 energy-saving air compressor station was held!

Deman's founder Huanjun Cen (left in the picture) presents the plaque to Changhua Changsheng's Executive Vice President Zengguang Li (right in the picture).

In the automotive parts industry (fastener industry chain)

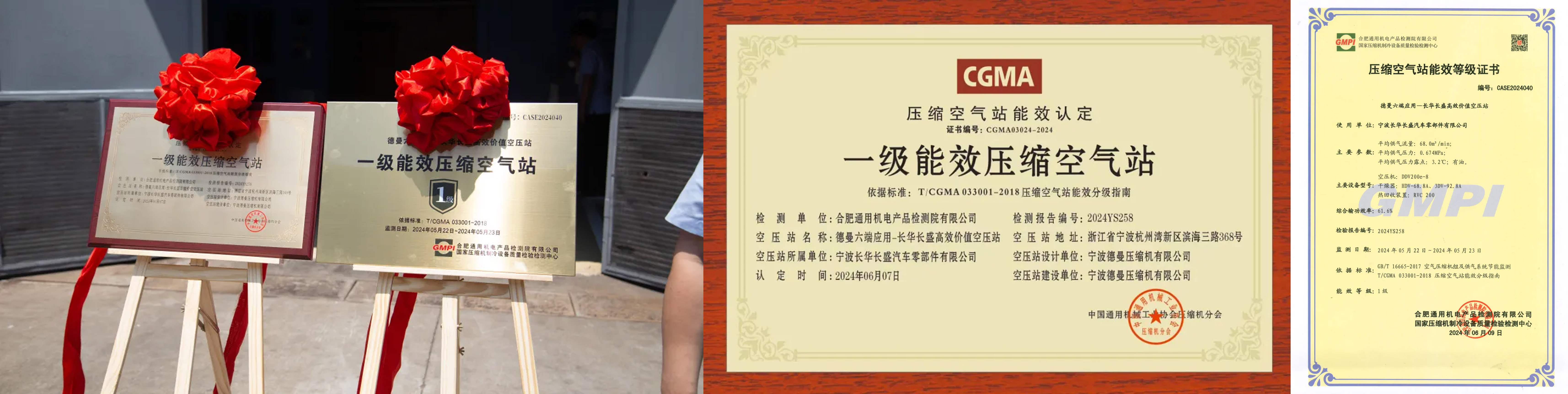

The first "Grade 1 energy efficiency compressed air station" with an installed power of 600 kilowatts and a total air production of more than 120 cubic meters.

Ningbo Changhua Changsheng Auto Parts Co., Ltd. is located on the south side of the Hangzhou Bay Bridge and is a subsidiary of Changhua Holding Group. It has a very high reputation in the automotive parts industry and has established long-term and stable cooperative relationships with automobile manufacturers such as Dongfeng Honda, FAW-Volkswagen, SAIC General Motors, GAC Honda, GAC Toyota, Dongfeng Nissan, Changan Ford, and GAC Mitsubishi.

In response to the pain points of high energy consumption, frequent faults, high maintenance costs, and untimely after-sales service of the original air compressor station, the Deman application engineer team has made a comprehensive layout from the “Six-End” (planning end, air production end, air transmission end, application end, cloud management end, and maintenance end), to accurately formulate a whole-plant efficient air usage solution for Changhua Changsheng.

After the implementation and acceptance of the solution, Changhua Changsheng's air compressor station has been upgraded from the original Grade 4 energy efficiency to a super Grade 1 energy efficiency. The overall energy saving rate of the station has reached 33.13%, saving 1.03 million kWh of electricity annually, reducing carbon emissions by 969 tons, equivalent to planting 53,000 trees! This has significantly reduced the comprehensive cost of production air usage!

After 24 hours of standard, continuous, and precise monitoring, the new air compressor station's transmission efficiency has reached 61.6%, which is 6.206% higher than the Grade 1 energy efficiency standard. It has passed the Grade 1 energy efficiency inspection and certification by the national authoritative testing unit, becoming the first Grade 1 energy efficiency compressed air station in the automotive parts industry (fastener industry chain) with an installed power of 600 kilowatts and a total air output of more than 120 cubic meters!

Deman "Six-End" Solution

① Planning End

From the moment Deman received the demand for energy-saving transformation from Changhua, the team of application engineers has made multiple visits to the customer's site for research and survey. From the early stages of planning, they have been formulating plans based on the standards of a first-grade energy efficiency station.

② Air Production End

After monitoring the original equipment data for 119 days × 24 hours and based on the actual production needs of the customer, Deman customized three DDV200e super first-grade energy-efficient pressure custom energy-saving air compressors with an outlet pressure of 0.68 MPa. These are paired with 5DV intelligent PM VSD super refrigerated air dryers and the "Air Commander" intelligent group control system. No matter how the workshop's air usage changes, the Deman air compressor station can operate at the best efficiency range.

③ Air Transmission End

Deman's super alloy aluminum pipeline is designed with full flow without reduction in diameter, featuring smooth inner walls that are corrosion-resistant and can maintain a constant pressure drop. By customizing stainless steel 45-degree three-way fittings and 45-degree elbows, the airflow from the air compressor can enter the main pipe more smoothly, reducing the loss in air transmission.

④ Application End

By installing a waste heat recovery system, the waste heat from the air compressor is used to heat the cleaning water pool, replacing the previous method of steam heating. This not only reduces the consumption of steam but also maximizes the reduction of the air compressor's operating power, further achieving energy saving and carbon emission reduction!

⑤ Cloud Management End

Deman's independently innovated "Deman Cloud" intelligent service control platform achieves digital management of the air compressor station for customers. While reducing the cost of manual operation and maintenance, it assists customers in making clearer judgments about the air production costs of the air compressor station.

⑥ Application End

In China, Deman offers a 10-year warranty on the entire machine, ensuring zero maintenance costs for customers over ten years. Each machine is installed with an IoT system. In case of any abnormal alerts, the Deman Service Center will immediately dispatch professional service engineers to the site to troubleshoot the issues. With the spirit of "the best doctors treat before illness occurs," potential problems are preemptively resolved, maintaining all machine indicators in an optimal state. This ensures safety and reduces the decline in the machine's air production efficiency in the later stages.