Case Study – Zhejiang Ouluntai Fire Protection Equipment Co., Ltd.

Zhejiang Ouluntai Fire Protection Equipment Co., Ltd. was established in 1988 and is located in Yuyao, Ningbo, Zhejiang Province. It is a leading benchmark enterprise in China’s fire extinguisher manufacturing industry. It's main compressed air applications are in hardware stamping, metal processing, and surface treatment.

Due to multiple issues with their original compressed air system, Ouluntai turned to us for a comprehensive upgrade.

Customer Challenges Before the Upgrade:

1. High operating costs

2. Excessive moisture content

3. High failure rate of the equipment

4. Delayed and inadequate service support

5. Inability to achieve dynamic load matching among multiple units

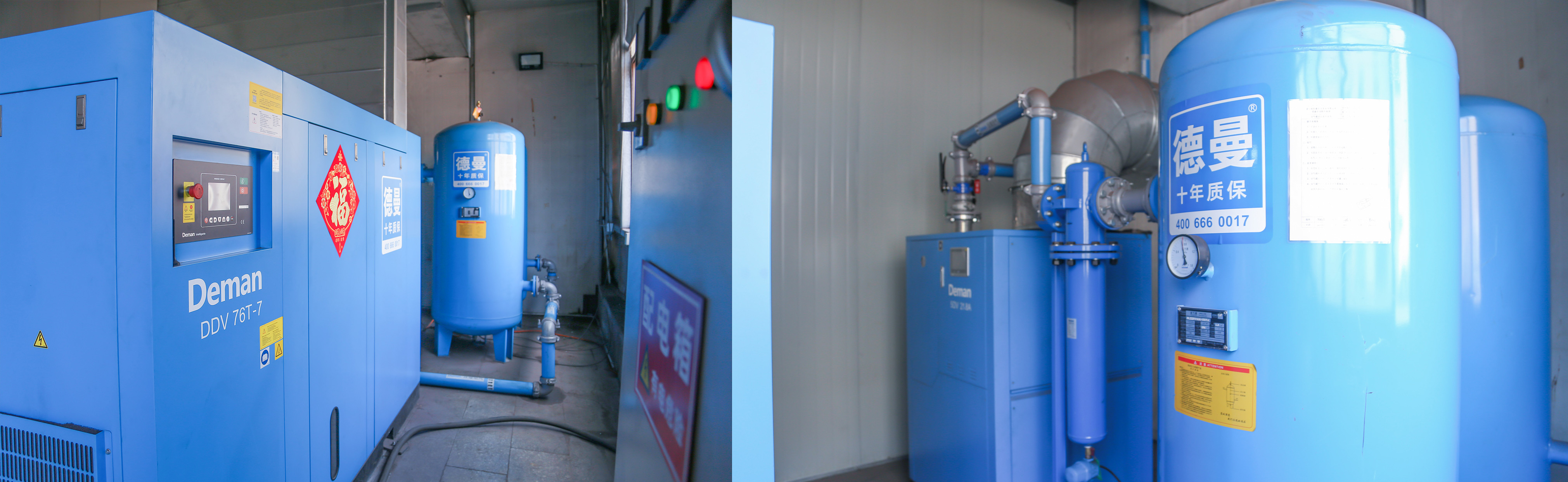

After multiple site visits, surveys, and measurements, Deman promptly provided a tailor-made, high-efficiency compressed air solution for the entire plant, specifically designed to support lean production in the fire protection industry.

Deman's Air System Comprises of:

1. Deman customized ultra-high efficiency air compressors

2. 5DV PM VSD refrigerated air dryer

① Excellent water removal capability with stable PDP

② Maximizes efficiency utilization

3. Aluminum alloy green super pipeline system

① Greatly cuts energy loss

② Super safe, reliable and durable

4. “Air Commander” multi-compressor central control system + “Deman Cloud” intelligent remote monitoring and control system

①Maintains each unit within its most efficient operating range and promptly adjusts to any deviations

②Continuously monitor and ensure the safe running of each installed machine

5. Experienced and fast-response after-sales service

6. “Six-end” application plan

①Planning ②Air production ③Air transmission ④Maintenance ⑤Cloud management ⑥Application

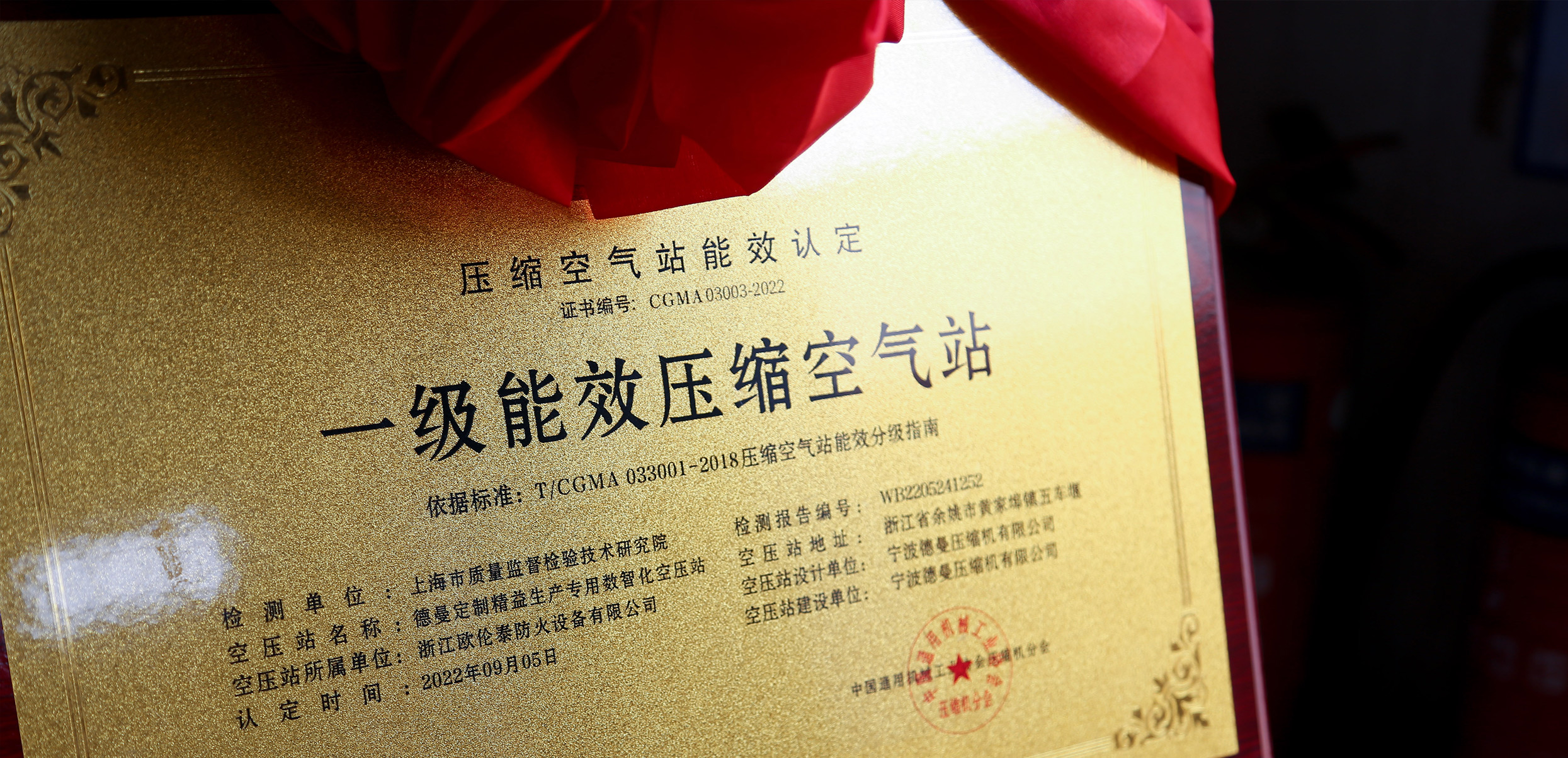

Ultimately, even before installing the heat recovery system, the new air station achieved a power transmission efficiency of 59.3%, exceeding the Class 1 energy efficiency standard by 7.8% and qualifying as a "Class 1 Energy Efficiency Compressed Air Station".

It is also the first "Class 1 Energy Efficiency Compressed Air Station" in China’s fire protection equipment industry!

After Installation of Deman System:

√ Super safety and stability system operation

√ Power transmission efficiency reaches 59.3%, exceeding the Class 1 energy efficiency standard by 7.8%

√ Annual electricity savings: 250,000 kWh

√ Annual carbon reduction≈236 tons

√ Equivalent to planting 59,000 trees

☆ The first "Class 1 Energy Efficiency Compressed Air Station" in China’s fire protection equipment industry