Case Study – Zhejiang Newchuwa Wool Co., Ltd. (Wool Textile Industry)

Zhejiang Newchuwa Wool Co., Ltd., established in 2003 and located in Jiaxing, Zhejiang Province, is a wholly owned subsidiary of Zhejiang Xinao Textile Co., Ltd.

The company specializes in wool textile processing and dyeing & finishing, including the production, sales, and import-export trade of wool tops and lanolin. In 2024, it achieved an operating revenue of RMB 1.752 billion.

Newchuwa has always placed great emphasis on energy efficiency management. However, the imported air compressors previously in use had become outdated, with poor energy performance and insufficient service support.

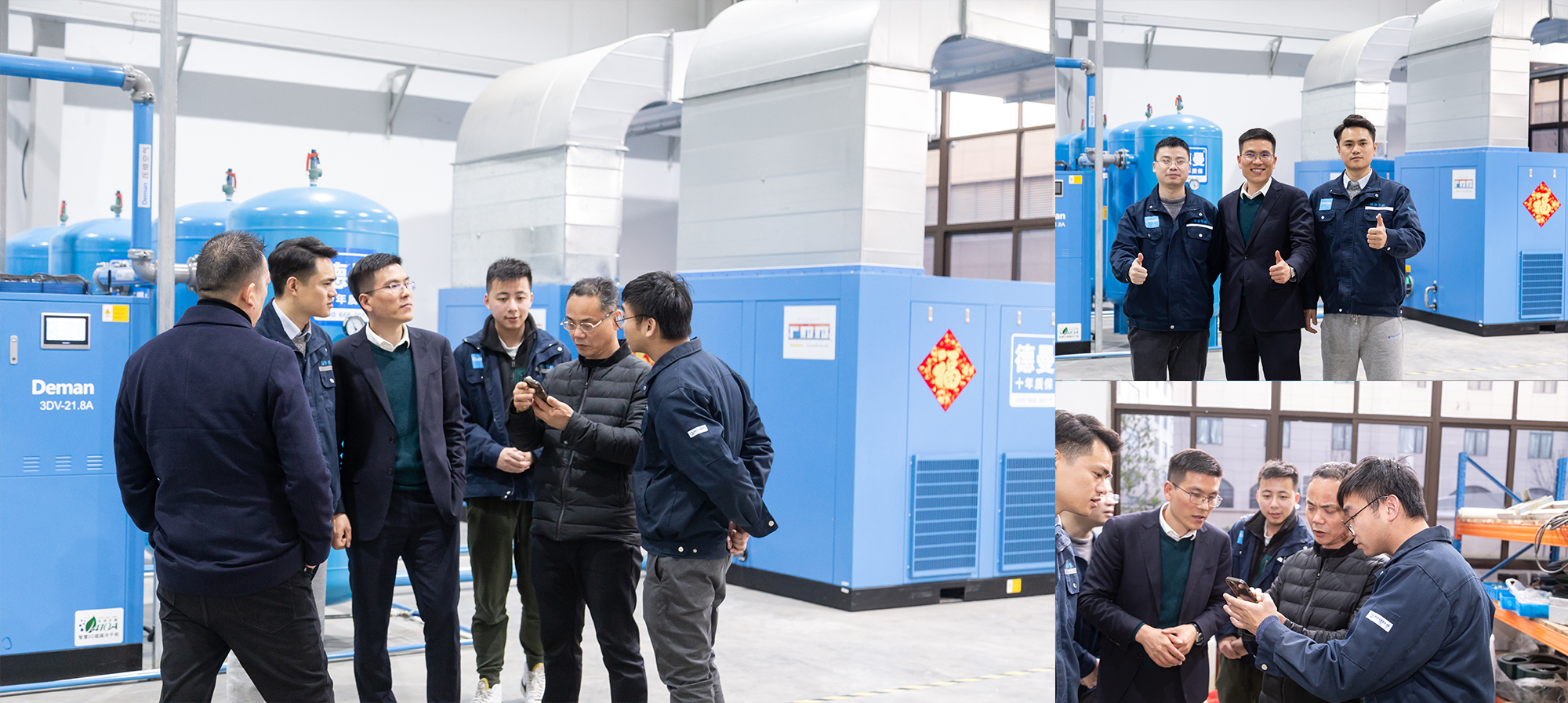

Several years ago, Newchuwa had already become acquainted with Deman and held high expectations for its excellent service, professionalism, and energy-saving performance. So when the company expanded and launched new projects, Deman was the first name that came to mind.

After communicating with several major air compressor brands and conducting a comprehensive comparison of energy-saving data and service capabilities, Newchuwa finally chose Deman.

Customer Challenges Before the Upgrade:

Old Device: a well-known Japanese Brand

·Previous average consumption per unit: 0.113 kW·H/Nm³

·Old equipment with poor energy efficiency

·After-sales service is inadequate

In the early stages of the project upgrade, we conducted in-depth on-site investigations, surveys, and testings to fully understand their system’s energy efficiency, pressure loss, and air loss. And finally made a customized solution for them.

Deman's Air System Comprises of:

·New Device: Deman Ultra-efficient Customized DDV110-8

·5DV PM VSD refrigerated air dryers

·Aluminum alloy super piping system

·Zero-air-consumption Drainage System

·“Air Commander” multi-compressor central control system + “Deman Cloud” intelligent remote monitoring and control system

·Customized energy-saving plan ensures optimal air usage across plant-wide with six-end application

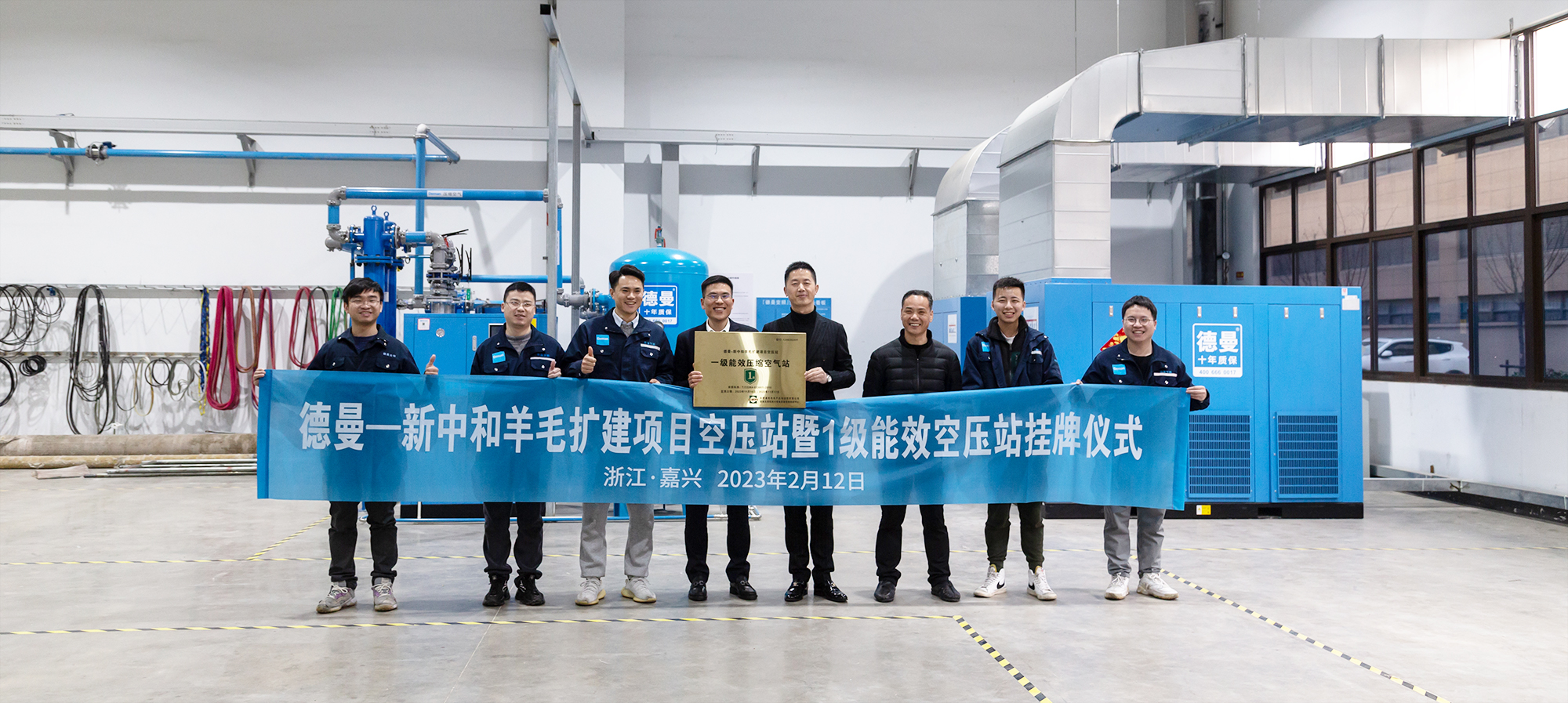

After the project upgrade, Deman’s compressed air system perfectly met the customer’s multiple requirements in terms of safety, energy efficiency, heat dissipation, noise reduction, cleanliness, and intelligent control — while also delivering significant cost savings.

After Installation of Deman System:

√ Current average consumption per unit: 0.09 kW·H/Nm³

√ Energy savings per hour after renovation (19Nm³/min): (0.113-0.09)*60*19=26 kWh/hour

√ Annual electricity savings≈190,000 kWh (≈189,000 RMB)

√ Annual carbon reduction≈178 tons

√ Equivalent to planting 44,600 trees

√ Power transmission efficiency reaches 56.1%, higher than the Class 1 energy efficiency standard (≥55%)

☆The first "Class 1 Energy Efficiency Compressed Air Station" in Jiaxing

In 2024, Newchuwa was recognized as a municipal-level Green Factory in Jiaxing.